| Screen (feet) | Size (mm) | 1 deck m3 | 2 deck m3 | 3 deck m3 | 1440 r.p.m. |

|---|---|---|---|---|---|

| 6x3 | 1830x915 | 4.1 | 4.95 | 5.5 | 05/07/05 |

| 8x4 | 2440x1220 | 7 | 8.5 | 10 | 07/05/10 |

| 10x4 | 3050x1220 | 8.2 | 9 | 11.6 | 07/05/15 |

| 12x4 | 3660x1200 | 9.9 | 11.85 | 13.85 | 10/20/08 |

| 15x5 | 3660x1525 | 13.6 | 17.4 | 20.4 | 15-30 |

| 20x7 | 6096x2133 | 24.5 | 32.31 | 38.1 | 20-40 |

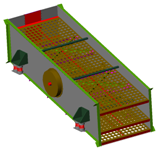

Features & Benefits

The main advantages are: Higher Screening Efficiency

- Long Life

- Economical

- Less Space

- Less Maintenance

- Easily Replaceable

- Screening Surface

Details

BODY: The body of Vibrating Screen is consists of base frame and screen supporting structure. The base frame is welded using heavy channels and angles and special care has been taken during design. Screen supporting structure and Screen are made from wear resistant special Coil Steels.

BEARINGS: Self lubricating heavy duty double row roller, self aligning bearings have been provided to hold the centre shaft with screen supporting structure.

CENTRE SHAFT: This shaft is made from special steel and it is supported at both ends by means of two roller bearings. Two eccentric dead weights have been provided on both ends to generate vibrations with the help of driving pulley.

DRIVING MOTOR: The foundation frame of the driving motor is provided by projection on one side of the Vibrating Screen and supports from base frame are also provided to hold the motor foundation. The size of motor varies as per the size of Vibrating Screen. Normally squirrel cage motor of 960 RPM is provided with the screen.

SPRING: Suitable helical coilded springs are provided with the Vibrating Screen. Entire screen holding structure is supported by these springs. Special care has been taken to manufacture these springs which bear entire load along with continuous vibratory process. These springs can easily be replaced by news ones when required.

SCREEN: The screens are made from special coilded sheets to provide sufficient resistance to excess wear and tear. The hole size of the screening surgface can be made as per the requirements of the customer. For each deck, screen surface is made from single sheet metal and shretched lengthwise to provide robust constructional service. The number of screening surface depends upon the number of decks of the screen. The inclination is given to the screen according to the suitability of work.

DRIVING PULLEY: The pully is provided on one side of the centre shaft with two v-grooves on it. It is directly coupled with driving motor with the help of 2 Nos. of v-belts. The dia of driving pully has been calculated as per the requirement of No. of vibrations per second.

ECCENTRIC SHAFT: Dead weights with eccentricity on there centre are provided on both the sides of the centre which generate the vibratory action. The size of dead weight and its eccentricity vary as per the design value for each and every screen.

NO. OF VIBRATION: 16 to 18 per second.

NO. OF DECK: Normally – 2(3 or 4 deck vibrating Screens are provided against special request). In case of 3 or 4 deck Vibrating Screen one special collecting (discharge) hopper is also provided.

Reviews

There are no reviews yet.