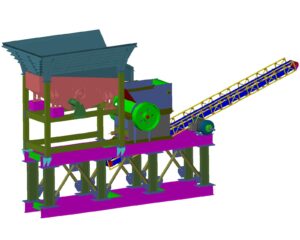

Skid-Mounted Stone Crushing Plants

Maximising Efficiency with HPPA

What is a Skid-Mounted Crushing Plant?

At the heart of our offerings are skid-mounted crushing plant, designed for easy erection and commissioning at your project site. The skid-mounted crushing plants have garnered widespread acclaim, thanks to their efficiency and seamless integration. Place an order!

Specifications include:

- 2-stage and 3-stage

- Capacity : 20 TPH to 200 TPH

- Feed size : 300 mm and below

- Output size : 40 mm and below

- Price : INR 1.0 – 3.5 crore

- Power Source : Electricity or diesel generators

- Flexibility : Customized based on specific requirements

Skid-Mounted Assembly Process

In our modern workshops, the equipment is placed on a self-supporting structure, inspected, and shipped with a few items for on-site assembly. This modular approach significantly reduces erection, assembly, and start-up time, translating to substantial savings in labor, supervision, and coordination costs at your end.

How Skid-Mounted Stone Crushing Plants Work?

Skid-mounted plants are designed for easy transportation to different job sites. They are pre-assembled on skids, allowing for quick installation and setup.

Primary Components:

- Feeder: Transports the raw material to the crusher.

- Crusher: Breaks down the large rocks into smaller pieces.

- Conveyor belts: Transport the processed material to various stages of the process.

- Vibrating screen: Separates the crushed material into different sizes.

Types of Skid-Mounted Plants:

- Jaw Crusher Plants: Ideal for primary crushing of hard rocks.

- Cone Crusher Plants: Suitable for secondary and tertiary crushing.

- Impact Crusher Plants: Effective for processing various types of rocks.

- Screening Plants: Specifically designed for efficient screening of materials

Checklist for Choosing the Best Skid-Mounted Crushing Plant:

- Type of Material: Consider the type of stone or mineral you are processing.

- Production Capacity: Determine the required production capacity per hour or per day.

- Size of Output Material: Ensure the plant can produce the desired size of crushed material.

- Mobility Requirements: Assess the need for frequent relocation and choose a plant with suitable mobility.

- Power Source: Decide between electric or diesel-powered plants based on site conditions.

- Ease of Maintenance: Opt for plants with easy maintenance features to minimize downtime.

- Customization Options: Choose a plant that can be tailored to meet specific project requirements.

- Operational Costs: Consider the overall operational costs, including fuel consumption and maintenance.

- Environmental Compliance: Ensure the plant complies with environmental regulations and emission standards.

- Reviews and References: Research and read reviews about the manufacturer and specific plant model.

- Warranty and Support: Check the warranty offered by the manufacturer and the availability of technical support.

- Safety Features: Verify that the plant has safety features to protect operators during operation and maintenance

Why Choose HPPA Skid-Mounted Crushing Plants?

- Accelerated Project Timelines: Customers are increasingly opting for skid-mounted plants due to their ability to fast-track projects. The integrated fast-track execution ensures quick assembly at the site, minimizing downtime and accelerating project timelines.

- Quality Assurance: Our skid construction is carried out under the vigilant eye of experienced engineers at the factory, reducing the likelihood of errors. This method, conducted in controlled workshop conditions, ensures fast, clean, and reliable manufacturing. Qualification tests are performed before delivery, providing an extra layer of quality assurance.

- Easy Relocation: Skid-mounted plants boast easy relocation capabilities, allowing for greater flexibility compared to traditional on-site erected plants. The reduced on-site erection time (as low as 8 hours) ensures minimal disruption, making them an ideal choice for projects with tight schedules.

- Cost-Effective Investment: Choosing skid-mounted turn-key plants translates to low overall investment costs. The efficiency in assembly and reduced on-site requirements contribute to a financially sound decision for your project.